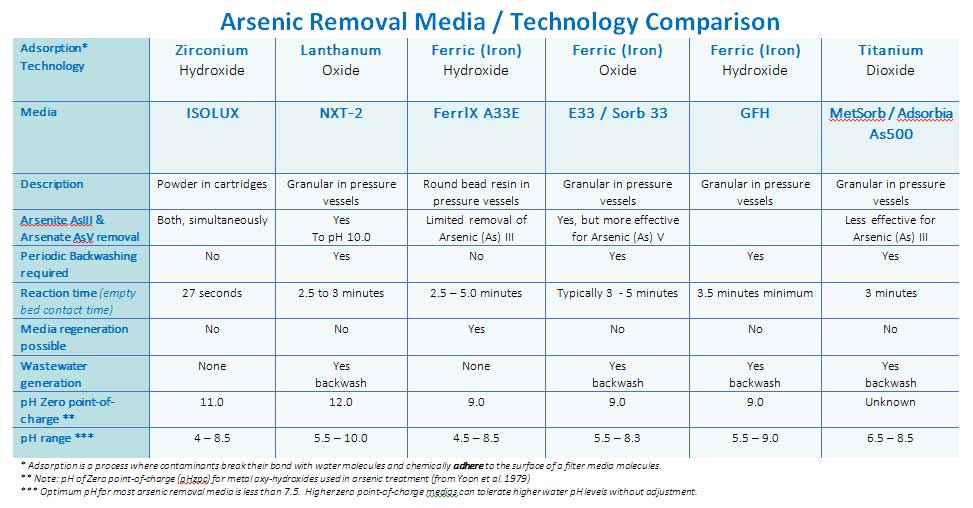

Not all arsenic removal media is alike.

The ISOLUX® Zirconium Technology Makes for a Truly Unique Removal Media.

The patented Zirconium Hydroxide adsorption media sets ISOLUX® shoulders above all other arsenic treatment technologies. Until now, you might not have heard of it, but Zirconium has been used for decades worldwide for arsenic removal.

ISOLUX® Zirconium media is the only arsenic removal media in the industry in powder form. Powder has much more surface area than the typical granules. Zirconium powder media gives ISOLUX® the ability to pull up virtually all the arsenic in a water stream in less than 30 seconds versus 3 to 5 minutes with granular medias. This fast uptake is precisely what makes the unique, no-backwashing, ISOLUX® cartridge technology possible.

- Unparalleled non-breakable, non-leachable arsenic bond.

- Verified for virtually non-detect (zero) arsenic removal.*

- Removes both AsIII and AsV, simultaneously, without pretreatment, chemicals or chlorination.

- Non-toxic.

- Media NSF 61 certified for drinking water use

- Imparts no odor, taste or color to water.

- Media bed residence time 27 seconds.

* Due to variances in influent water quality, users are urged to perform independent verification of the non-hazardous character of spent media cartridges. Additionally, some states may have disposal criteria different from Federal guidelines (TCLP).